The Core of ceiling Fan | The Difference Between AC Motor and DC Motor

AC motor

An AC motor is a type of electric motor that works by rotating on alternating current (AC) power. AC motors are used in household appliances such as vacuum cleaners, fans, blenders, and more.AC means that the voltage changes directions rapidly, which causes the electrons to move back and forth in an instant. This means it takes less time for an AC motor to rotate a full 360 degrees than it would for a DC motor because there are fewer moving parts required since there's no need for brushes or armature coils like those found in DC motors.

DC motor

A DC motor is a type of electric motor that works on direct current (DC). It was invented by Nikola Tesla, who was one of the most important inventors in history. The DC motor has been around since 1837 and has been used for many different applications, such as ceiling fans and washing machines.The rotor is connected to an external load such as a fan blade or belt. It's also connected to the shaft that connects it with the stator. And the stator provides magnetic support for the rotor by creating an electromagnetic field around itself. This allows it to rotate freely within its own axis, powered solely by electrical energy supplied from an external source like electricity generated through solar panels or wind turbines used by homeowners today."

What is the difference between a ceiling fan with a DC motor and an AC motor?

Typically, a DC motor is more energy-efficient, quieter, and more expensive than an AC motor. However, it is also more durable, reliable, and powerful. DC motors are available with different voltages; for example 12V or 24V. A 12V DC ceiling fan will be much smaller in size than its 24V counterpart but will also move less air due to its lower current rating (current is the flow of electrons).A DC motor can be run at any voltage between 6-12 V or 24 V without any change in performance or life span while AC motors require changing the capacitor value to suit different speeds as mentioned above. This makes them flexible enough to be used on multiple platforms such as cars, boats, etc...

Different gears, different speed

The primary reason DC motors cannot match the efficiency of AC motors is because of their fewer gears. When a motor’s gear ratio increases, so do its torque and efficiency. A DC motor has fewer gears than an AC motor, which means it has less torque and overall lower efficiency. Higher-torque motors also tend to be more expensive than low-torque ones because they require more materials, engineering time, and money to produce—which again makes them less economically viable than AC motors when you consider how much energy they use over time.The basic structure of DC motor

Theoretically, AC and DC are different in how they work, but the overall structure is similar. A motor converts electrical energy into mechanical energy. It's called a motor because it can convert one form of energy into another. For example, you might have an electric drill that uses electricity to spin a drill bit inside wood or metal.The difference between AC and DC is that they use different kinds of electrical current: alternating current (AC) and direct current (DC). In both cases, an electromagnet powers the rotor around the stator so that it spins. However, with AC power there are two cycles per second; with DC power there is only one cycle per second.

Comparing the structure of AC and DC motors

The structure of the two motors is very different. In an AC motor, current flows through a conductor in one direction, and then it reverses direction. This reversal of current causes a magnetic field to reverse directions as well. Because of this, an AC motor has more torque than a DC motor because there is less friction and more torque can be produced at lower RPMs than with a DC motor.

However, AC motors are not perfect either; they have their own disadvantages too! They are typically much larger than DC motors and require more maintenance because they have brushes that wear out faster (this happens over time). For this reason alone you should always consider choosing ceiling fans with brushless permanent magnet (BPM) motors instead if you can afford it!

What is speed regulation?

The speed regulation is the process of controlling the speed of a fan. It's accomplished by using one of three methods: changing the voltage, changing the frequency, or changing the phase. Voltage refers to the electrical potential that causes electrons to flow through an appliance (like your ceiling fan) at a certain rate and strength. The more voltage you apply to an appliance, the faster those electrons will travel; this means more power output from your ceiling fan motor. Frequency (or cycles per second) refers to how many times per second something happens; in this case, it's how many times each electrical cycle occurs (i.e., when an electron travels from one side of its circuit to another). By increasing or decreasing this number we can change how quickly our AC motor operates—which changes how fast everything moves! Phase refers to where an event starts within a cycle; for example, if there were two phases instead of just one then each phase would have its own starting point within that larger cycle instead of just both starting at once."AC and DC motors run at different speeds

An AC motor operates at a constant speed, regardless of load. In contrast, a DC motor varies its speed as the load varies.

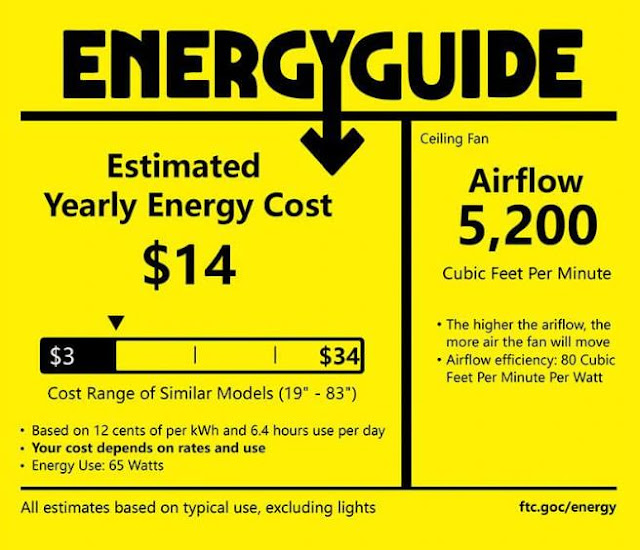

- In most cases, they use less energy – up to 70% less than a standard AC fan.

- They are generally extremely quiet.

- They will often have more speed options, the reverse function on the remote, and are generally faster to start, stop and change speed.

- The motor is generally more compact and lighter, which allows for a slimmer motor design.

A ceiling fan with a DC motor runs more energy-efficient than a ceiling fan with an AC motor

A ceiling fan with an AC (alternating current) motor can run at two speeds: high speed and low speed. When you turn on your ceiling fan, it will start rotating at high speed and then slow down when it reaches its maximum speed. If you want to change the direction of your fan, you have to reverse its direction by turning it off and then turning it on again. In other words, there's no difference between "turning off" and "turning on." The result is that these fans are very easy to operate but they use up more electricity than DC fans do because their motors have higher speeds throughout their rotations.

AC motors are more energy-efficient than DC motors because they don't waste power like DC motors do when they're running at low speeds or not being used at all--which means that if you don't require much air circulation from your fan (for example if there isn't much humidity in your room), using an AC motor could save money over time by reducing electricity costs for those times when there aren't any changes made about how quickly air circulates through them (or even none at all!)

The ceiling fan market is becoming more intelligent and efficient, and the ceiling fan motor is being updated and upgraded. There are many challenges facing DC motors, such as high cost and lack of mature technology. If these challenges can be overcome, then it will have a huge impact on the development of smart homes.

Comments

Post a Comment